brief

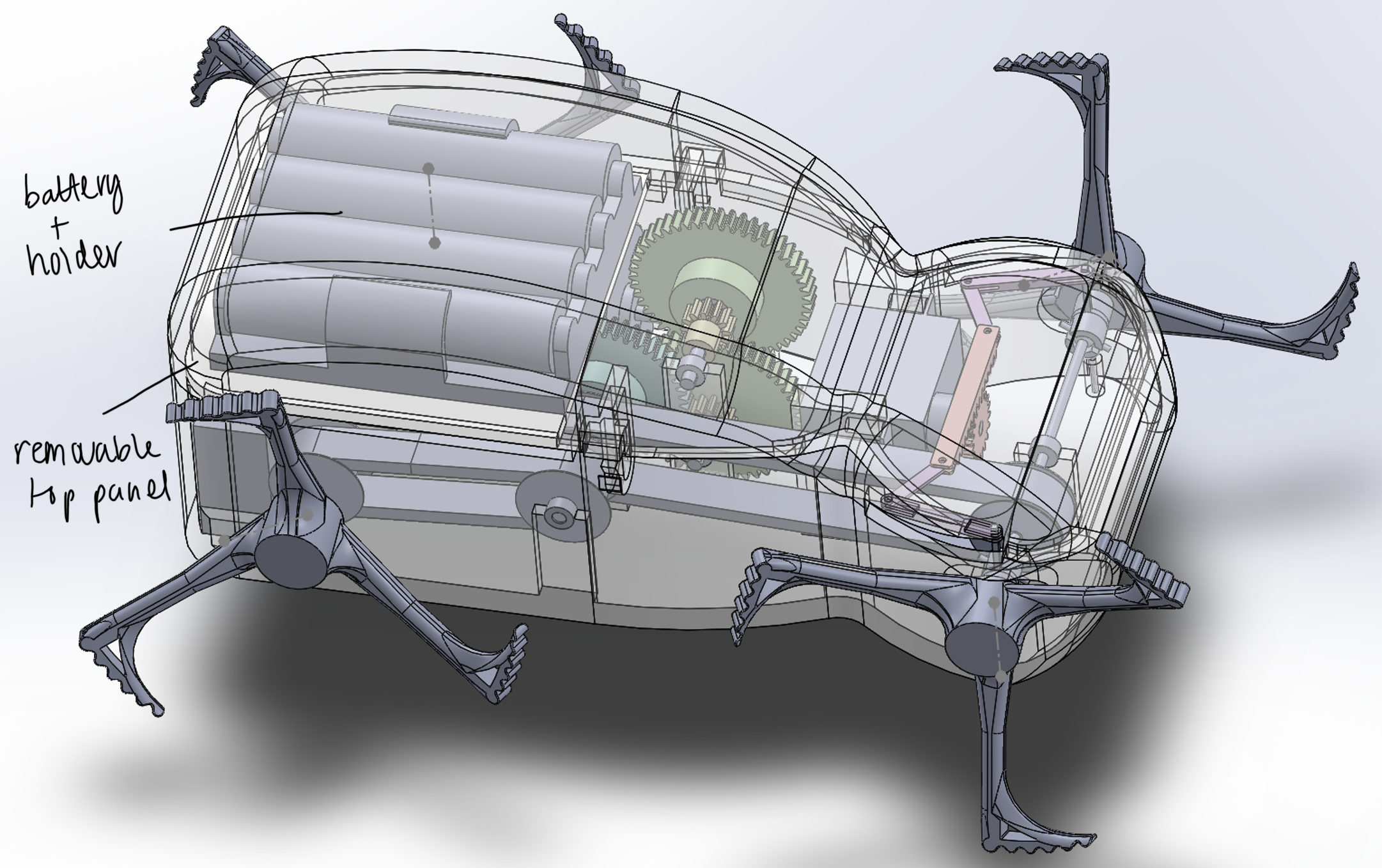

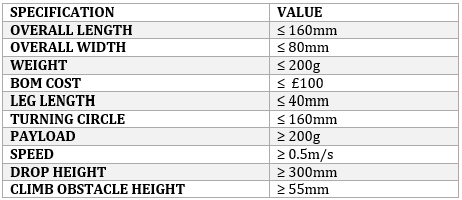

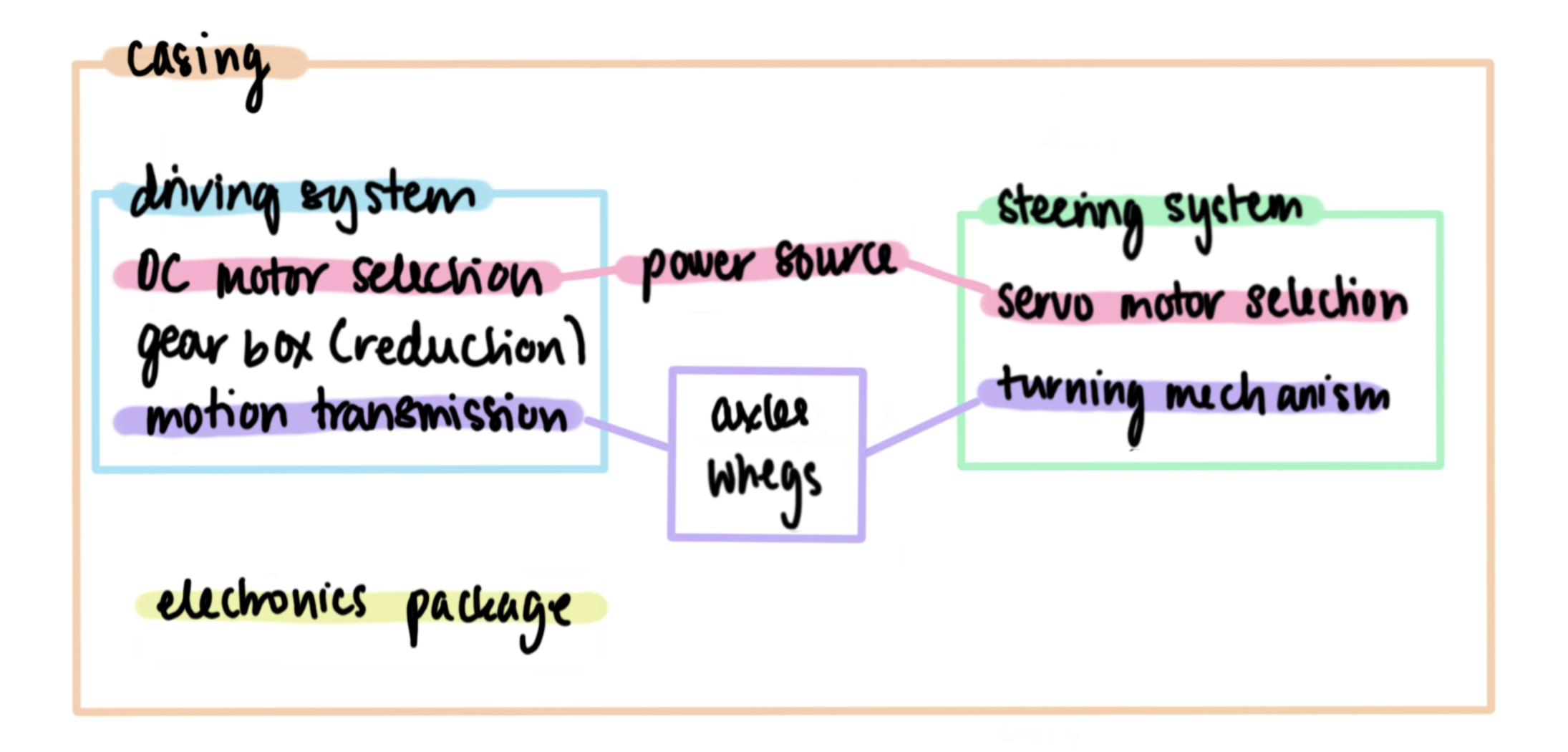

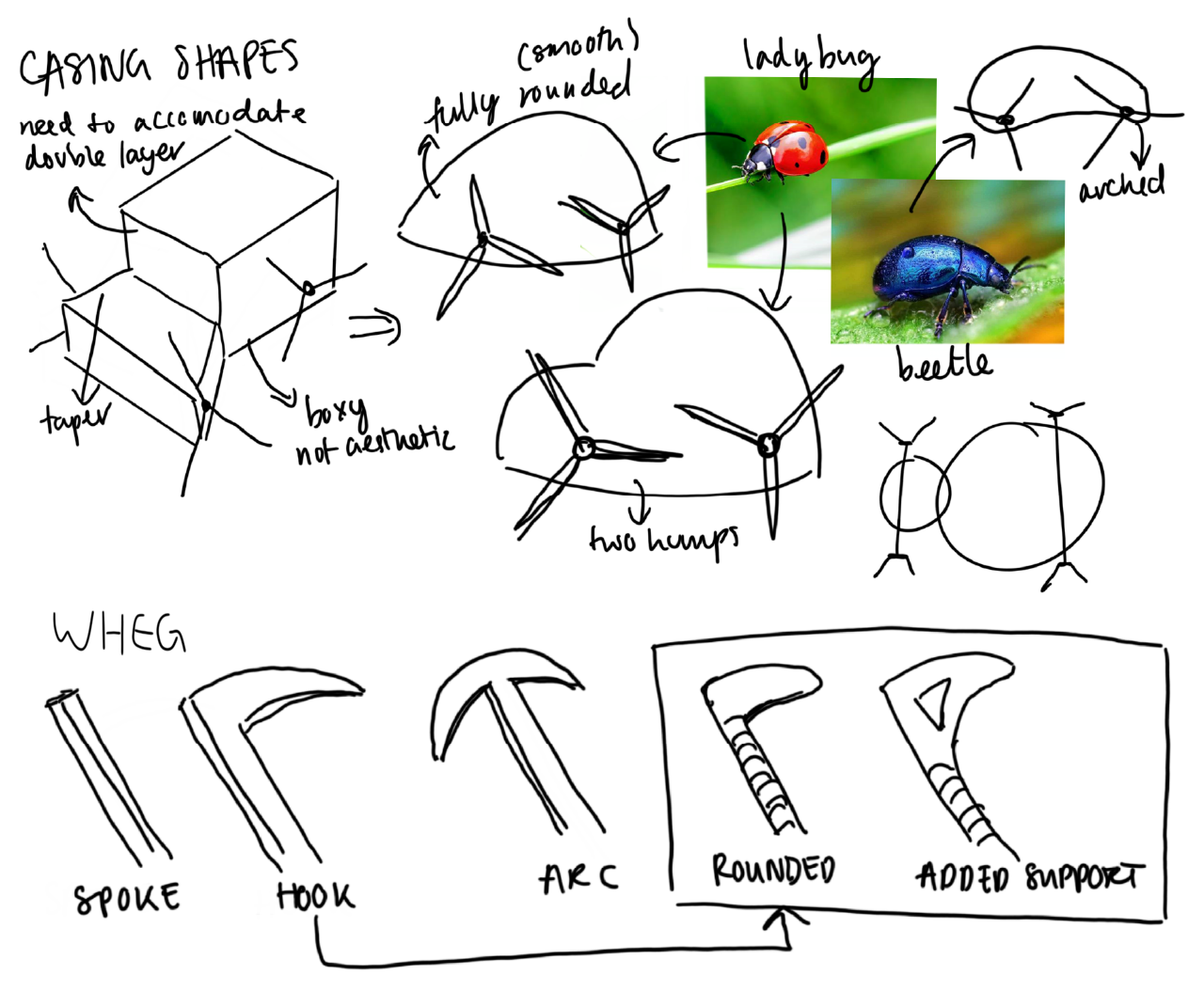

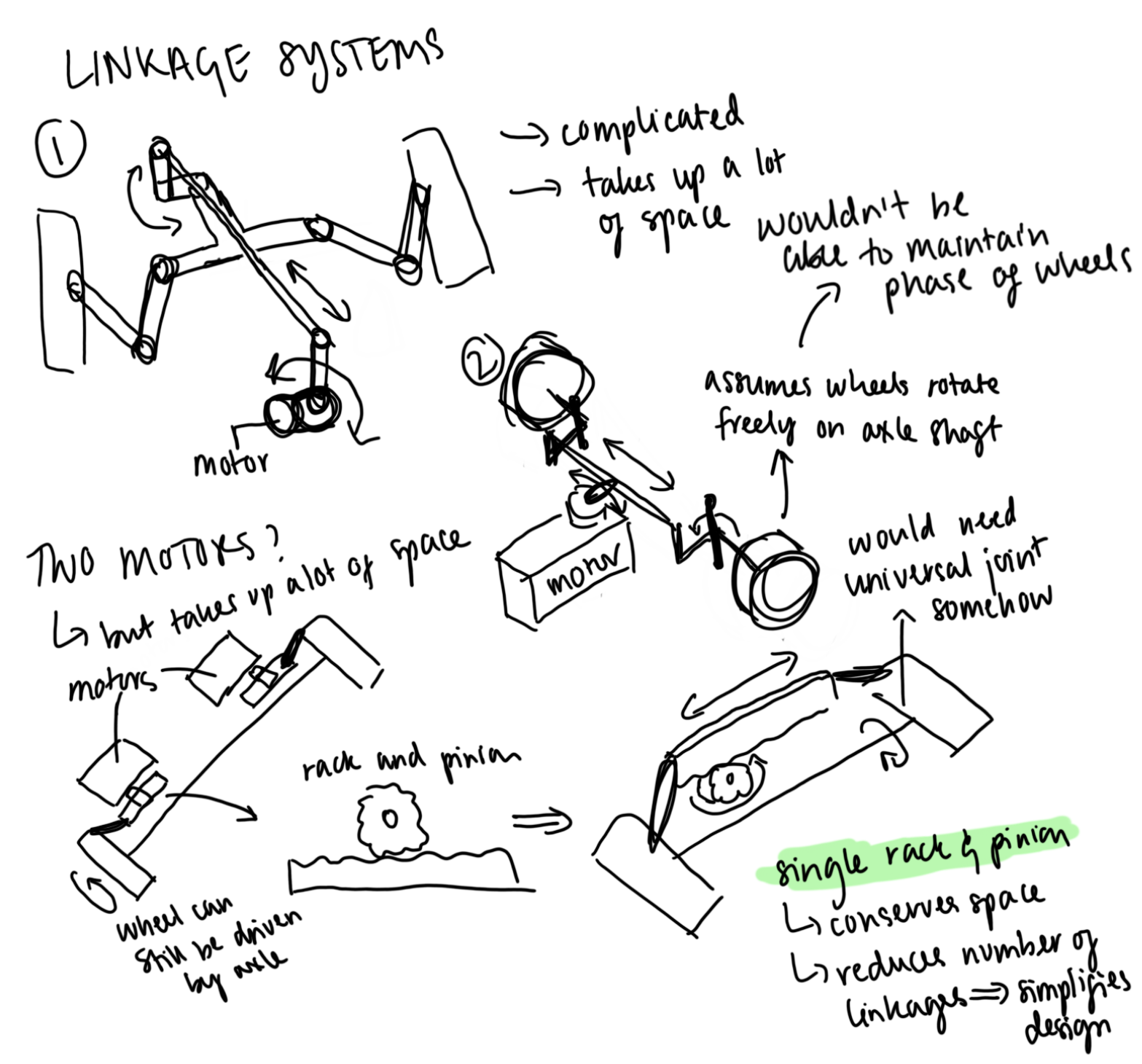

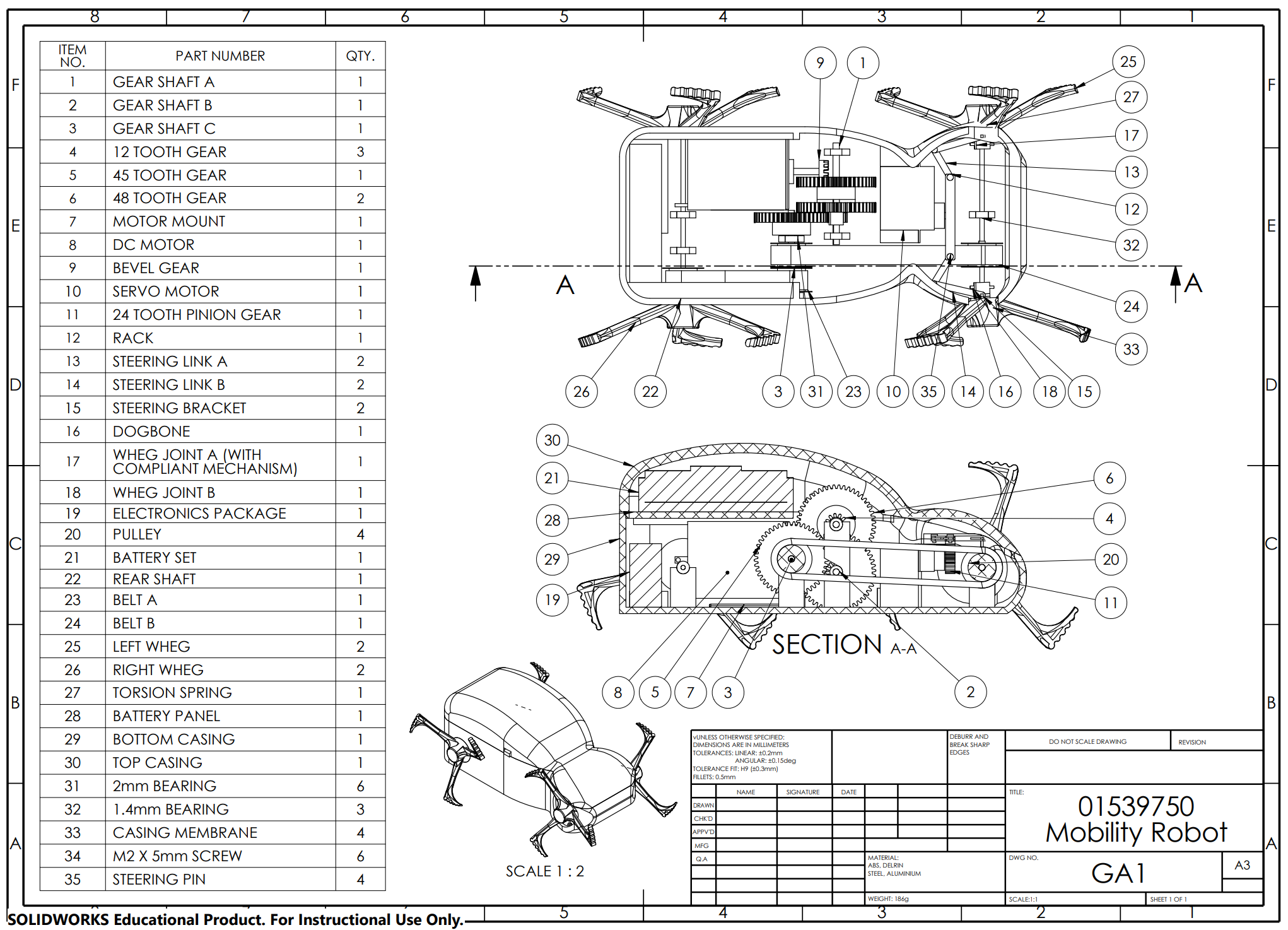

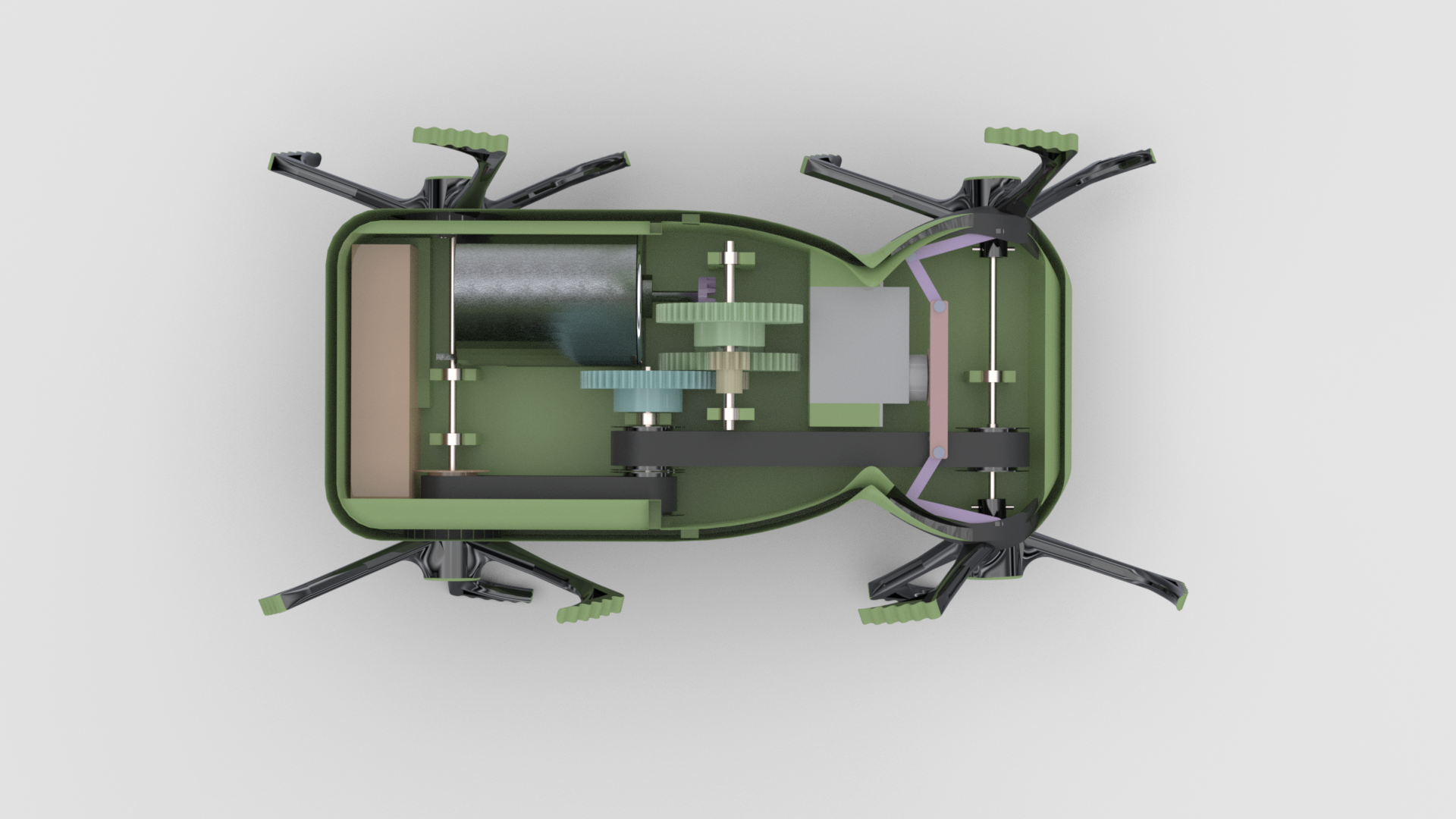

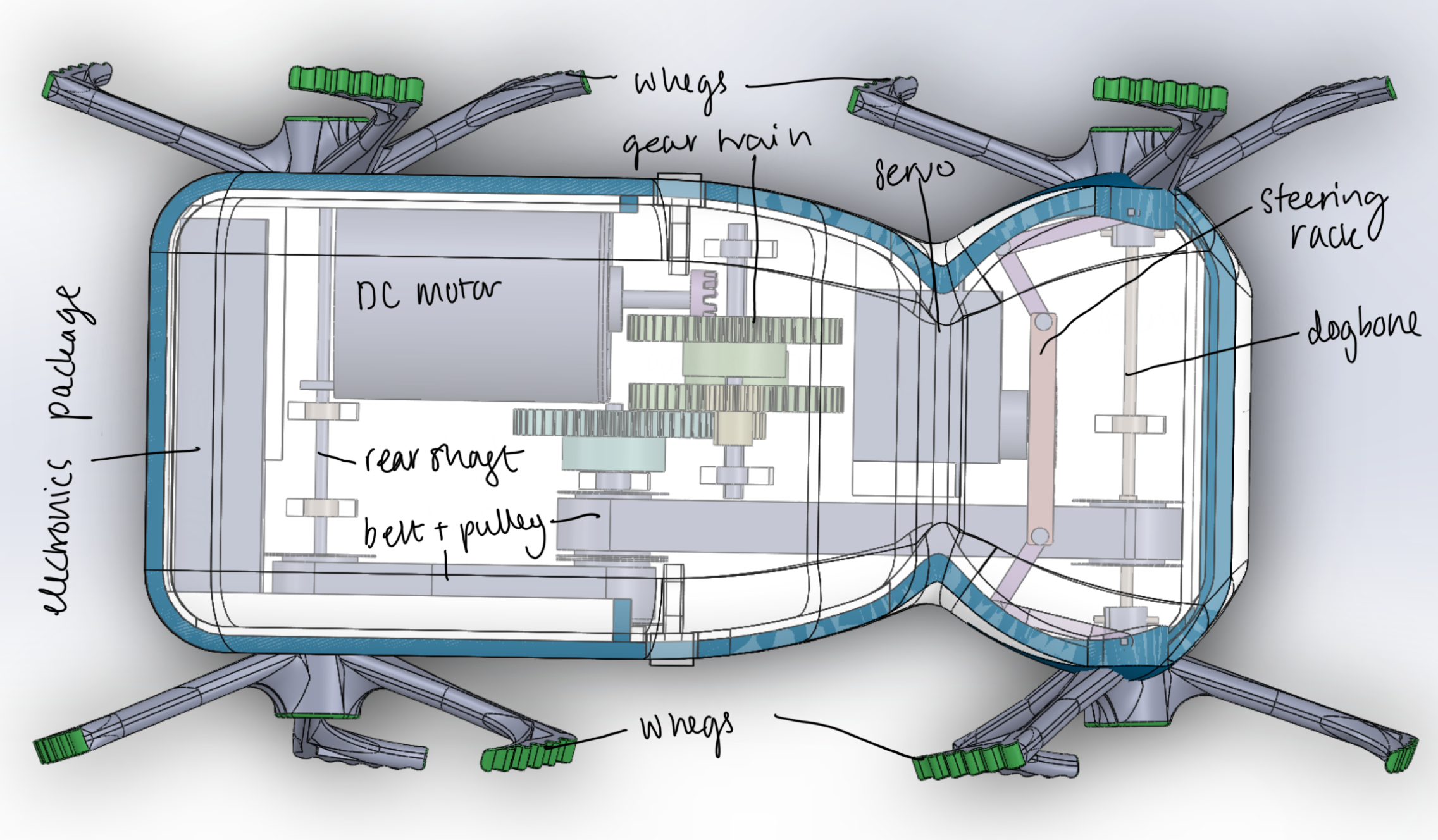

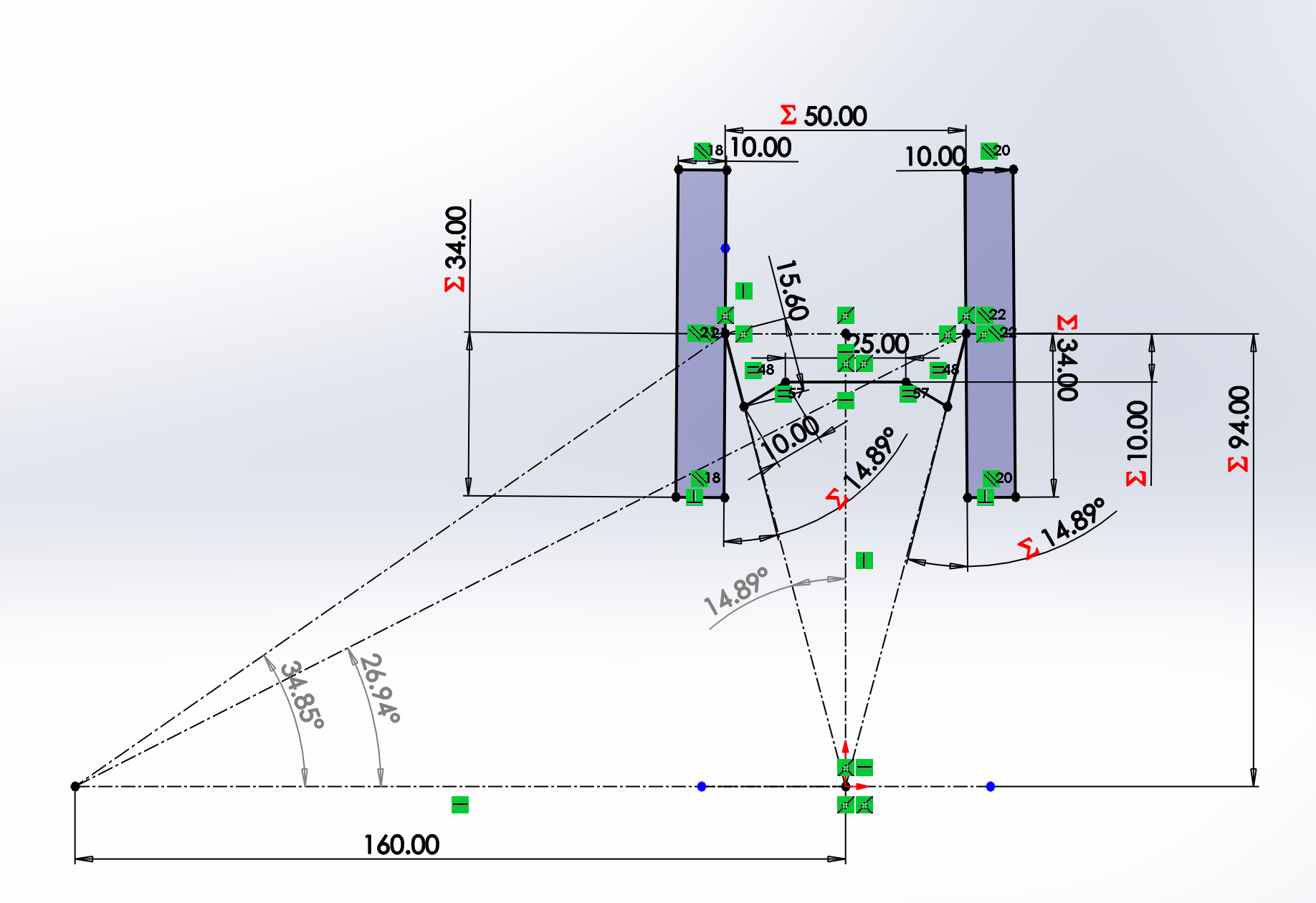

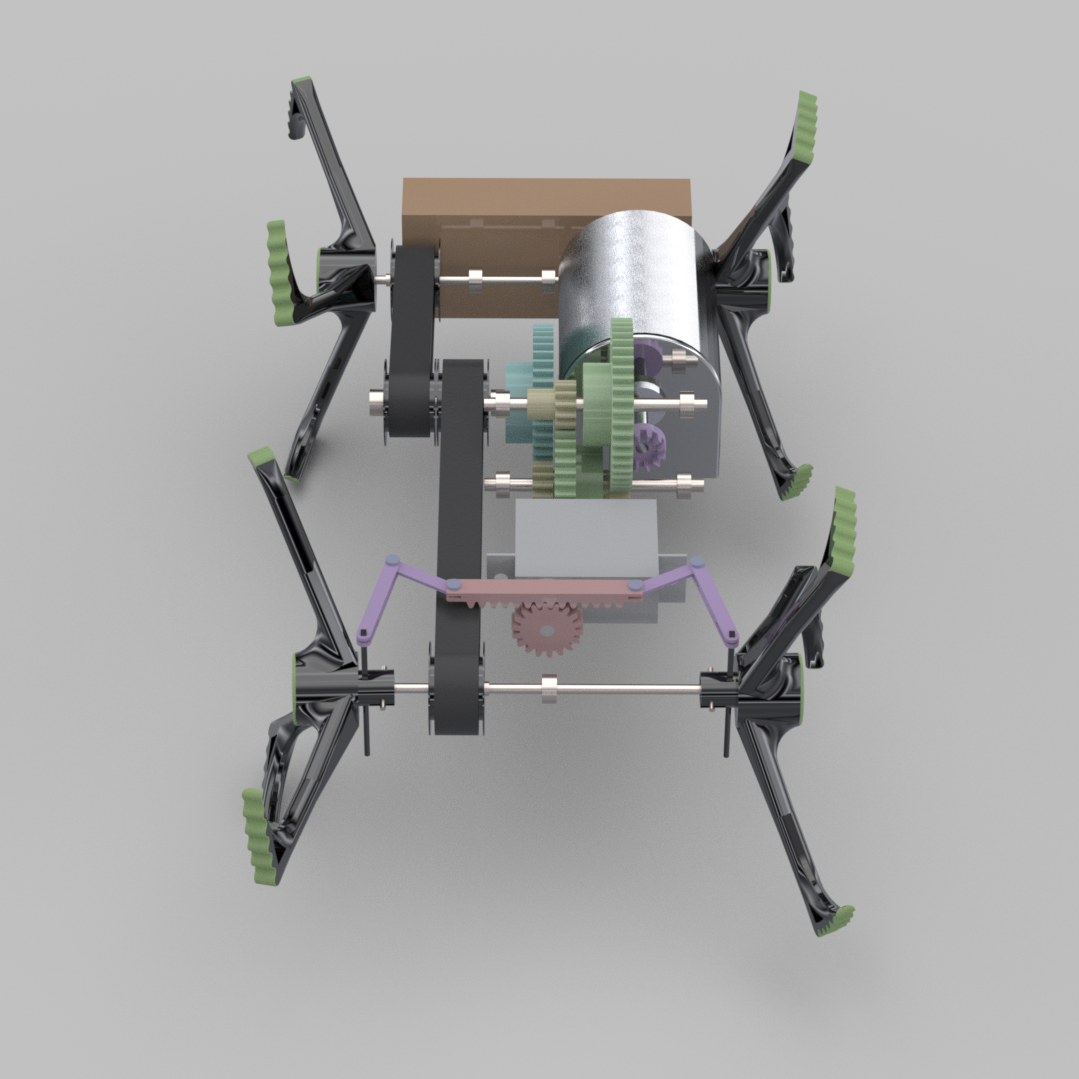

The challenge was to design a chassis and mobility system for an miniature robot that utilises three-spoked appendages as wheels. It was required to have a low profile body for optimum obstacle climbing, include a 45x20x10mm electronics package (excl. battery) and be suitable for Ingress Protection IP 53. Other specific performance requirements can be seen in the specification table.

outcomes

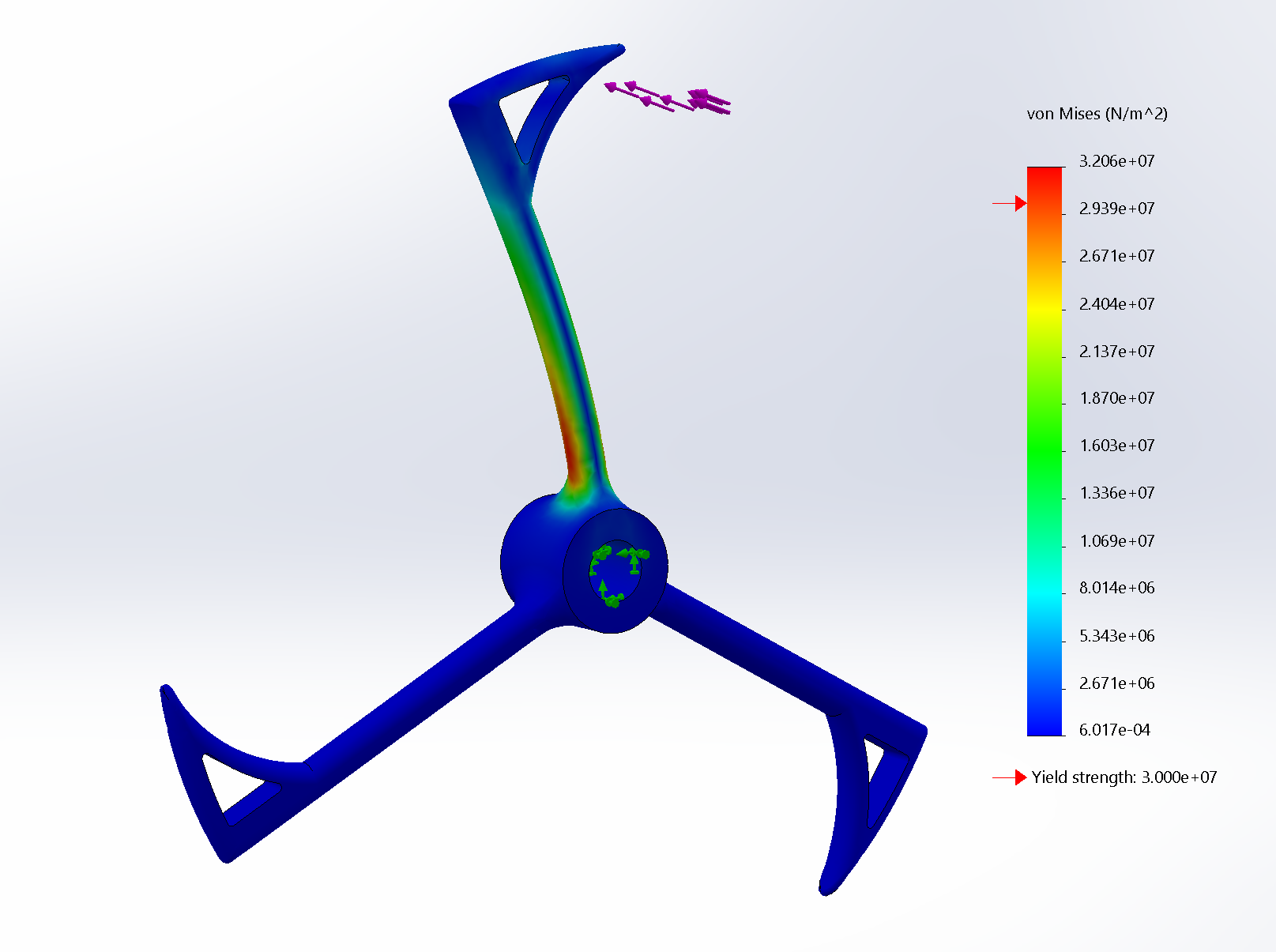

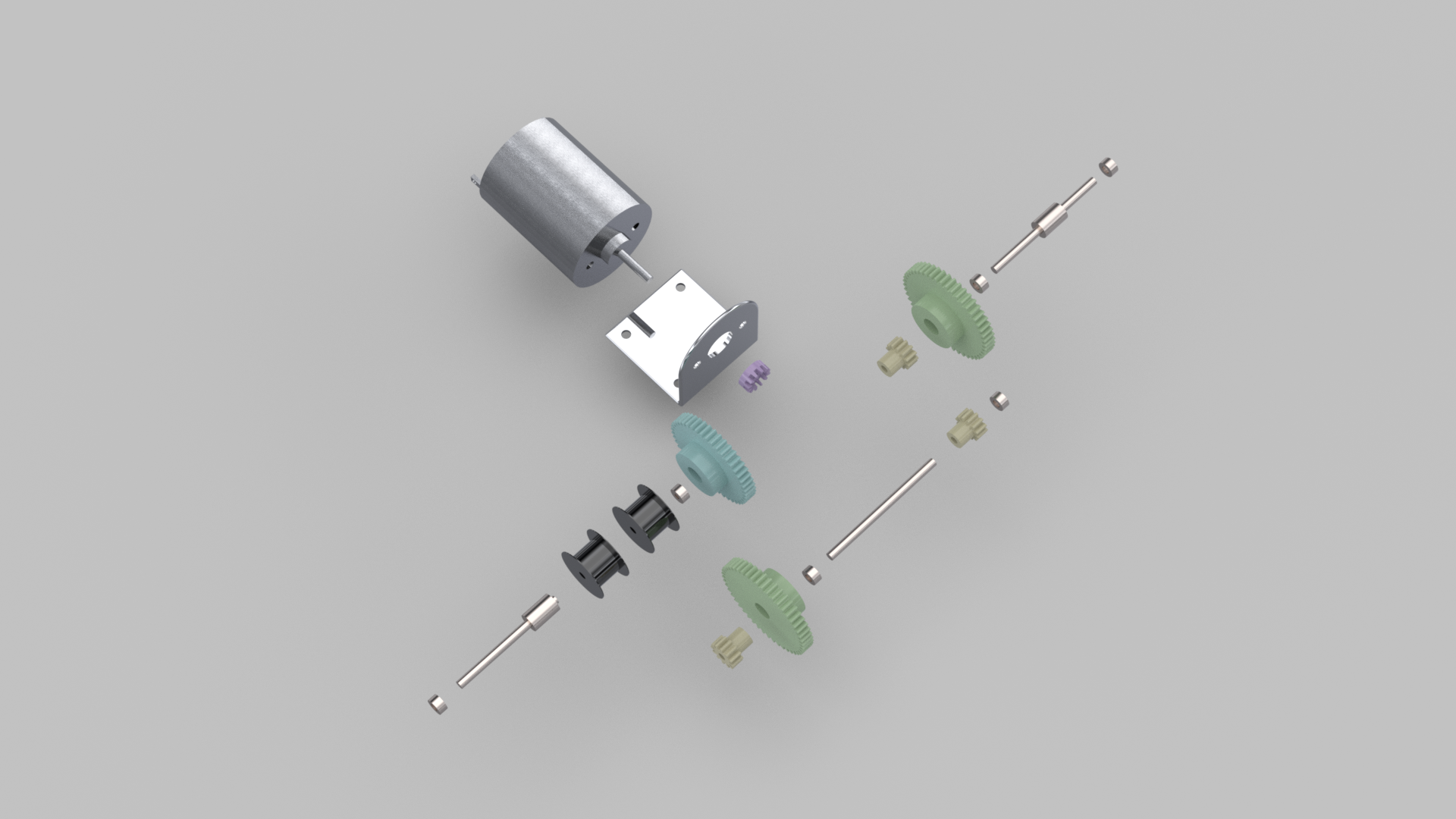

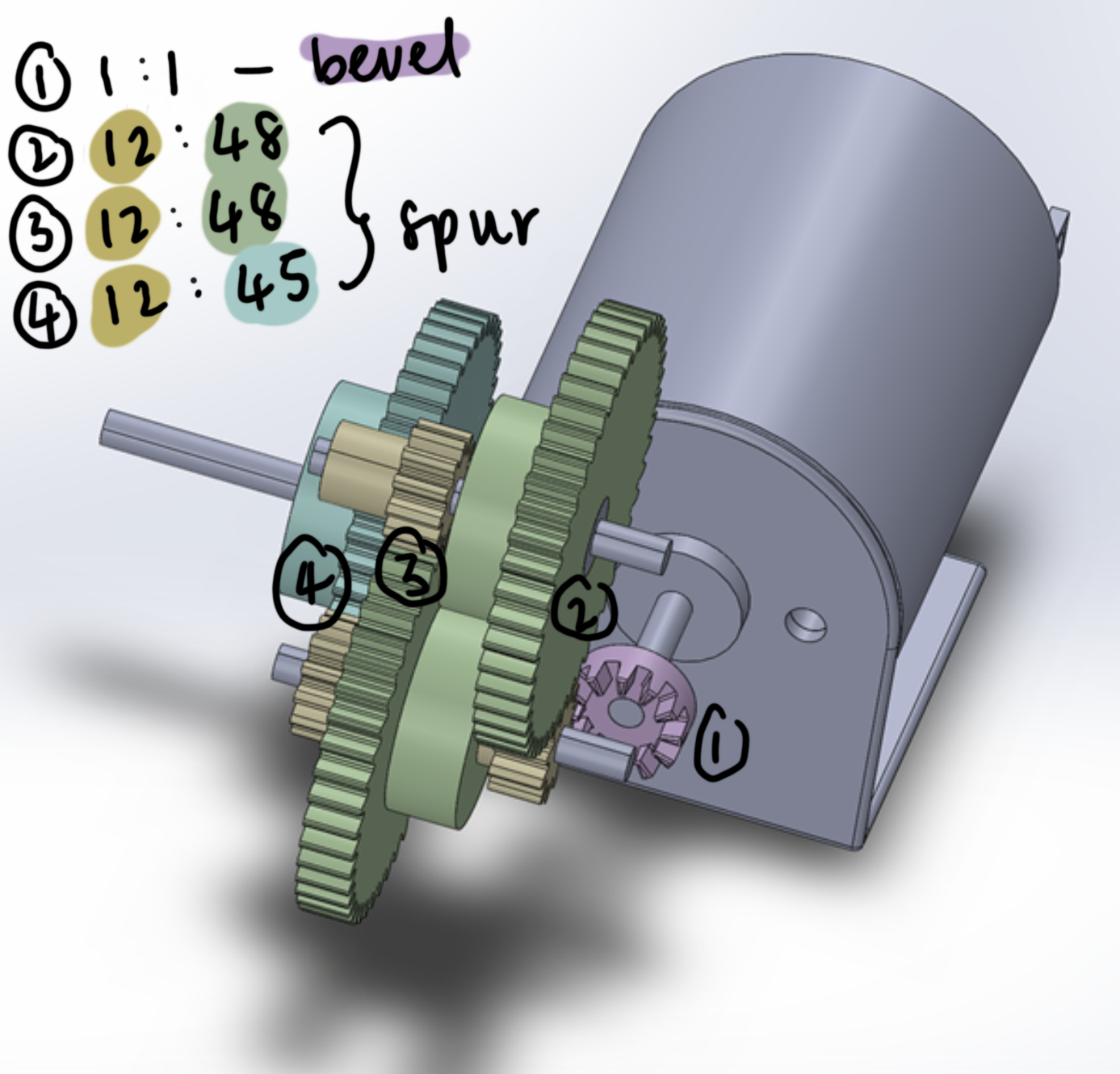

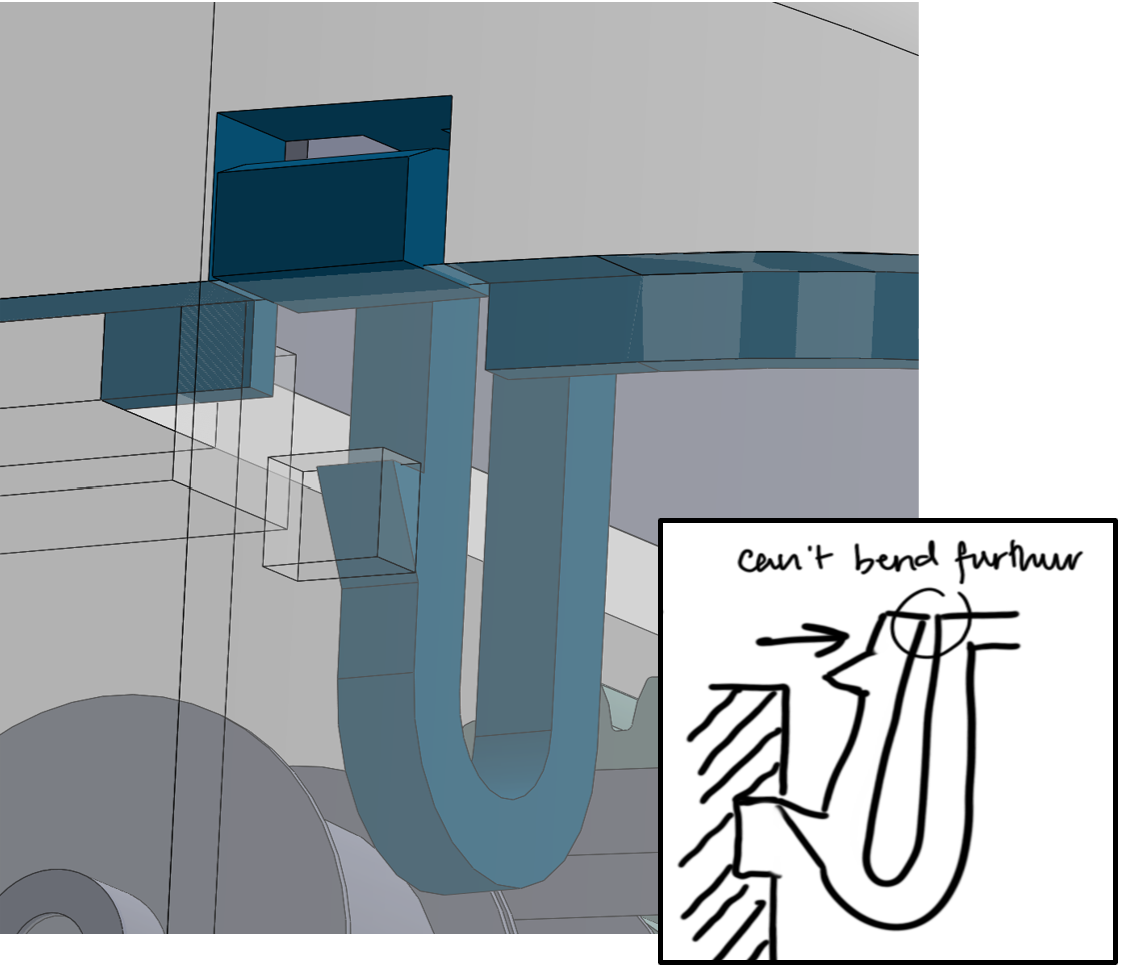

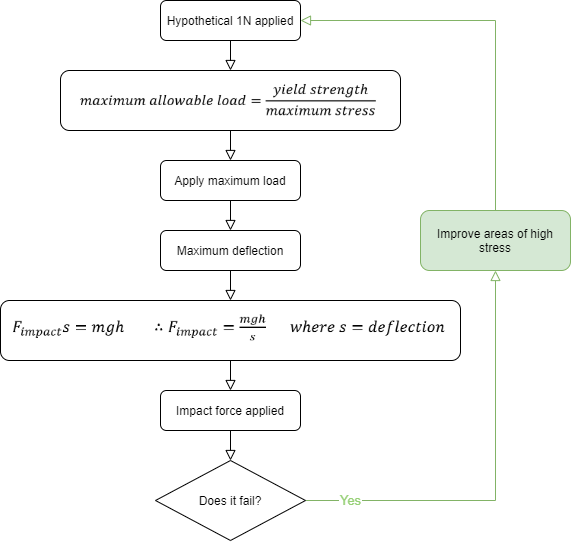

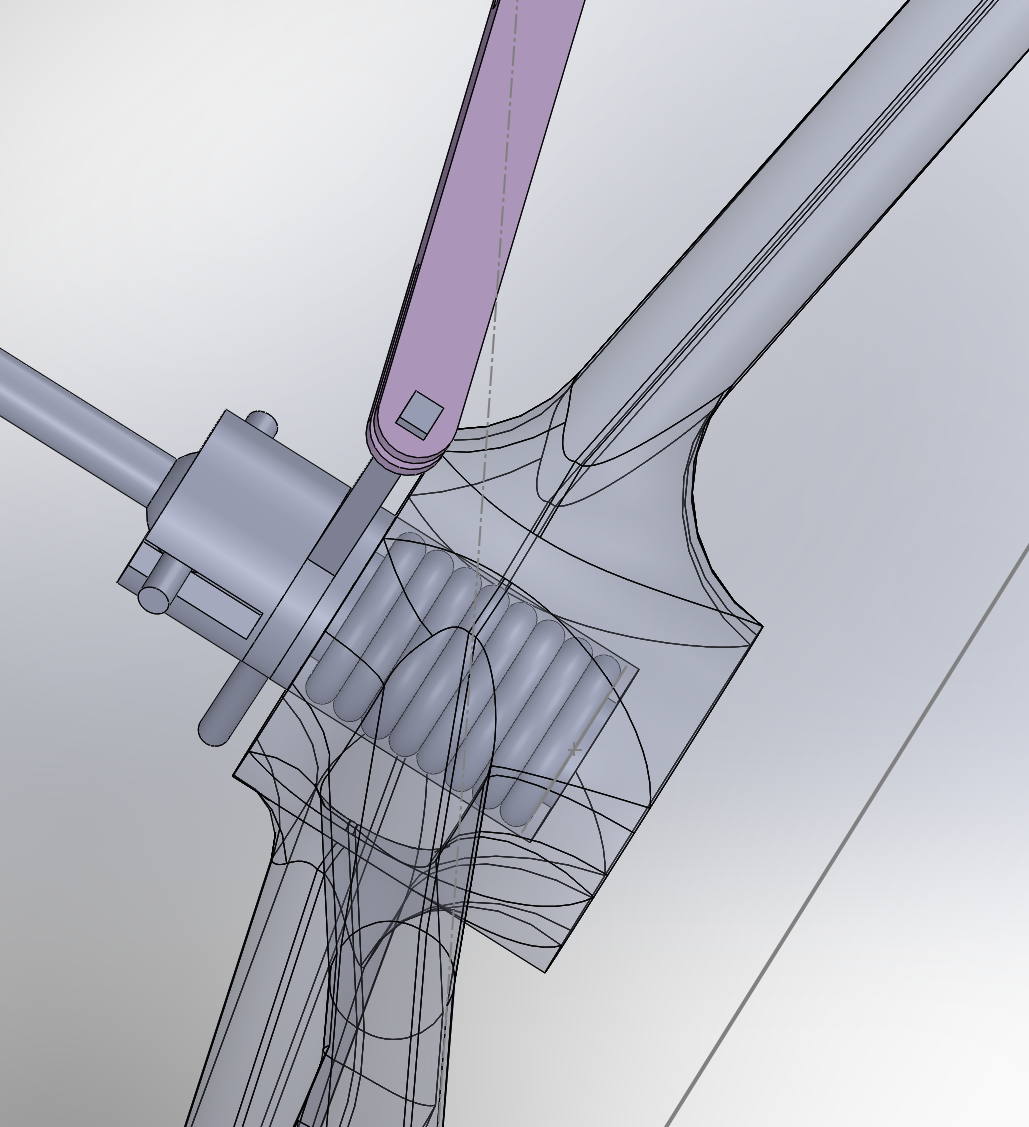

Many skills were gained in designing this robot, including the technical ability to CAD separate parts and combine them into a single complex assembly. The fabrication of the driving and steering system was one of my favourite aspects, especially in being able to apply motion studies to gain better understanding on how different components interact with each other within the assembly. The final concept was able to meet all the requirements as defined in the aforementioned specification. Decisions were guided by engineering analysis through calculations, computed using Microsoft Excel and through simulations, using the CAD software Solidworks. Notably, the final mass was 7% under the threshold set and 16% was saved on the total cost of manufacturing.